Technical solution for supplying permeate gas from Ca Mau gas processing plant to Ca Mau fertilizer plant

Abstract

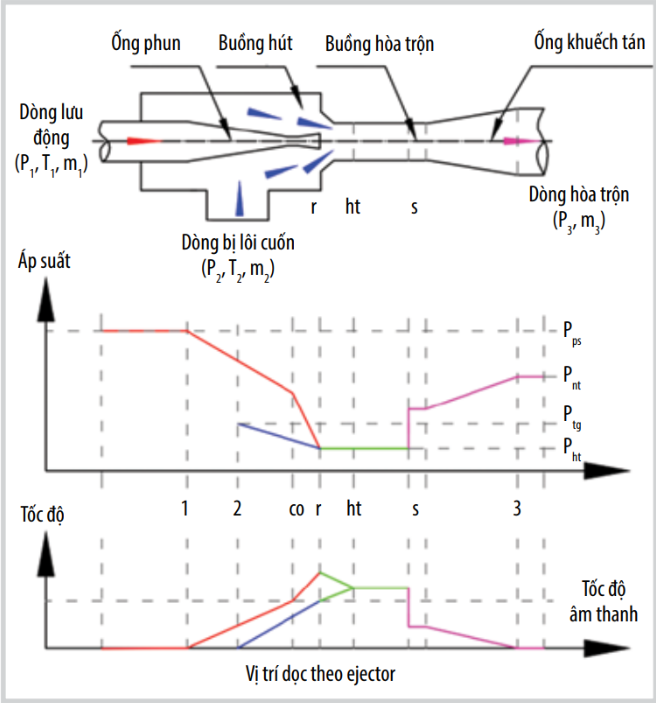

At Ca Mau Gas Processing Plant, the CO2 adjustment skid produces approximately 140 kSm3/day of permeate gas, of which 40 - 50 kSm3/ day is consumed as low-pressure fuel gas for heating systems. The remaining permeate gas of 90 - 100 kSm3/day is discharged to the flare, where it is burned along with gases associated with the processing. In order to recover and utilize the whole of permeate gas, the research team proposed a technological solution using a gas ejector to transfer the permeate gas to Ca Mau Fertilizer Plant. The recovered gas is then blended with natural gas and used as feedstock for urea production. This solution demonstrates the efficient utilization of permeate gas, optimizes the use of fuel sources and reduces greenhouse gas emissions.

References

PV GAS, “Báo cáo sáng kiến cung cấp permeate gas từ Nhà máy xử lý khí Cà Mau sử dụng cho Nhà máy Đạm Cà Mau năm 2019”, 2019.

Tổng công ty Dung dịch khoan và Hóa phẩm dầu khí, “Báo cáo tổng kết: Nghiên cứu sử dụng nguồn khí Permeate gas của GPP Cà Mau cho Nhà máy Đạm Cà Mau”, 2017.

J.R. Calvert and Roy A. Farrar, An engineering data book, 3rd edition. Bloomsbury, 2008.

PV Gas Project Management Company, “Supply of permeate gas to Ca Mau fertilizer plant - Process simulation report”, 2018. [5] PV GAS, “Permeate gas recovery from GPP Ca Mau - P&ID and PFD”, 2017.

B.J. Huang, J.M. Chang, C.P. Wang, and V.A. Petrenko, “A 1-D analysis of ejector performance”, International Journal of Refrigeration, Volume 22, Issue 5, pp. 354 - 364, 1999. DOI: 10.1016/S0140-7007(99)00004-3.

Nguyễn Văn Bình, Phạm Tuấn Anh, Nguyễn Trường Giang, và Nguyễn Duy Hải, “Giải pháp thu hồi khí Permeate từ Nhà máy Xử lý khí Cà Mau để làm nhiên liệu cho nồi hơi phụ trợ và lò đốt Reforming sơ cấp tại Nhà máy Đạm Cà Mau”, Tạp chí Dầu khí, Số 3, trang 30 - 38, 2021. DOI: 10.47800/PVJ.2021.03-04.

Nguyen Trung Kien and Le Chi Hiep, “Thermodynamic analysis of an ejector-vapour compressor cascade refrigeration system”, Journal of Thermal Analysis and Calorimetry, Volume 141, pp. 2189 - 2200, 2020. DOI: 10.1007/s10973-020-09635-6.

1. The Author assigns all copyright in and to the article (the Work) to the Petrovietnam Journal, including the right to publish, republish, transmit, sell and distribute the Work in whole or in part in electronic and print editions of the Journal, in all media of expression now known or later developed.

2. By this assignment of copyright to the Petrovietnam Journal, reproduction, posting, transmission, distribution or other use of the Work in whole or in part in any medium by the Author requires a full citation to the Journal, suitable in form and content as follows: title of article, authors’ names, journal title, volume, issue, year, copyright owner as specified in the Journal, DOI number. Links to the final article published on the website of the Journal are encouraged.