A technological solution combining Turbo expander and Joule-Thomson valve to enhance LPG recovery efficiency at the Dinh Co gas processing plant

Abstract

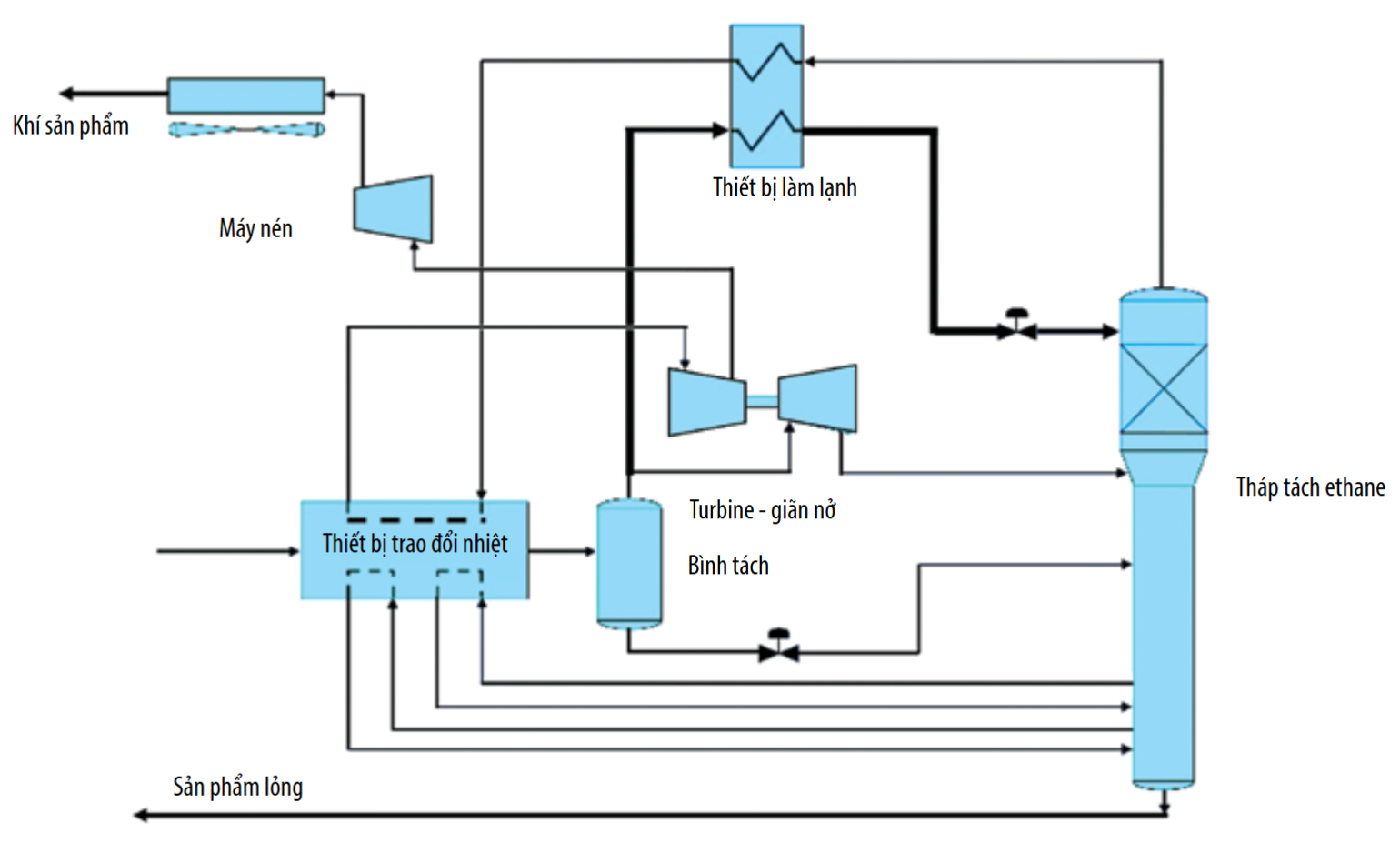

This paper presents the application of a low-temperature hydrocarbon recovery system that combines a turbo expander (TE) with a Joule- Thomson (JT) valve at the Dinh Co Gas Processing Plant. This is an advanced cryogenic cooling technology, widely applied in modern natural gas processing plants, LNG complexes, and petrochemical facilities that require high liquid recovery efficiency.

The implementation at Dinh Co Gas Processing Plant demonstrates that the combined TE-JT system achieves significantly deeper gas cooling compared to the JT valve-only configuration. As a result, propane (C3) recovery efficiency has consistently exceeded 85%, contributing to improved economic performance of the plant. The hybrid TE-JT solution not only proves its high practicality amid the volatility of energy and LPG markets but also represents a substantial advancement in the modernization of Vietnam's gas processing technologies, aligning with global trends toward energy efficiency improvement and emission reduction.

References

[2] Richard N. Pitman, Hank M. Hudson, John D. Wilkinson, and Kyle T. Cuellar, “Next generation processes for NGL/LPG recovery”, 77th Annual Convention of the Gas Processors Association, 16 March 1998.

[3] A. Guerrero, “Turbo-Expander training”, Atlas Copco Mafi-Trench Co. LLC, 2017.

[4] B. Linnhoff and D.R. Vredeveld, “Pinch technology has come of age”, Chemical Engineering Progress, Volume 80, Issue 7, pp. 33 - 40, 1984.

[5] B. Linnhoff, and E. Hindmarsh, “The pinch design method for heat exchanger networks”, Chemical Engineering Science, Volume 38, Issue 5, pp. 745 - 763, 1983. DOI: 10.1016/0009-2509(83)80185-7.

[6] B. Linnhoff and S. Ahmad, “Cost optimum heat exchanger networks”, Computers & Chemical Engineering, Volume 14, pp. 729 - 767, 1990.

[7] M. Shamsi, A.A. Obaid, M. Vaziri, S. Mousavian, A. Hekmatian, and M. Bonyadi, “A comprehensive comparison of the turbo-expander, Joule-Thomson, and combination of mechanical refrigeration and JT processes for natural gas liquids production”, Energy, Volume 295, pp. 131032, 2024. DOI: 10.1016/j.energy.2024.131032.

[8] Isidro Alejandro Argueta Flores, Ana Paula Meneguelo, Cintia Marangoni, Yuri Nascimento Nariyoshi, and Marcelo Silveira Bacelos, “Exergy and exergoeconomic analysis of the gas subcooled process for the Brazilian market”, ACS Omega, Volume 10, Issue 26, pp. 28092 - 28111, 2025. DOI: 10.1021/acsomega.5c02484.

[9] Yasna Pourmohammad, “Utilization of Turbo- Expander to generate power in natural gas extraction process”, Journal of Petroleum Science and Technology, Volume 11, Issue 1, pp. 29 - 34, 2021. DOI:10.22078/ jpst.2021.4161.1673.

[10] Ahmed Abd El-Kader Bhran, Mohamed Hassan Hassanean, and Mohamed Galal M.Helal, “Maximization of natural gas liquids production from an existing gas plant”, Egyptian Journal of Petroleum, Volume 25, Issue 3, pp. 333 - 341, 2016. DOI: 10.1016/j.ejpe.2015.08.003.

1. The Author assigns all copyright in and to the article (the Work) to the Petrovietnam Journal, including the right to publish, republish, transmit, sell and distribute the Work in whole or in part in electronic and print editions of the Journal, in all media of expression now known or later developed.

2. By this assignment of copyright to the Petrovietnam Journal, reproduction, posting, transmission, distribution or other use of the Work in whole or in part in any medium by the Author requires a full citation to the Journal, suitable in form and content as follows: title of article, authors’ names, journal title, volume, issue, year, copyright owner as specified in the Journal, DOI number. Links to the final article published on the website of the Journal are encouraged.